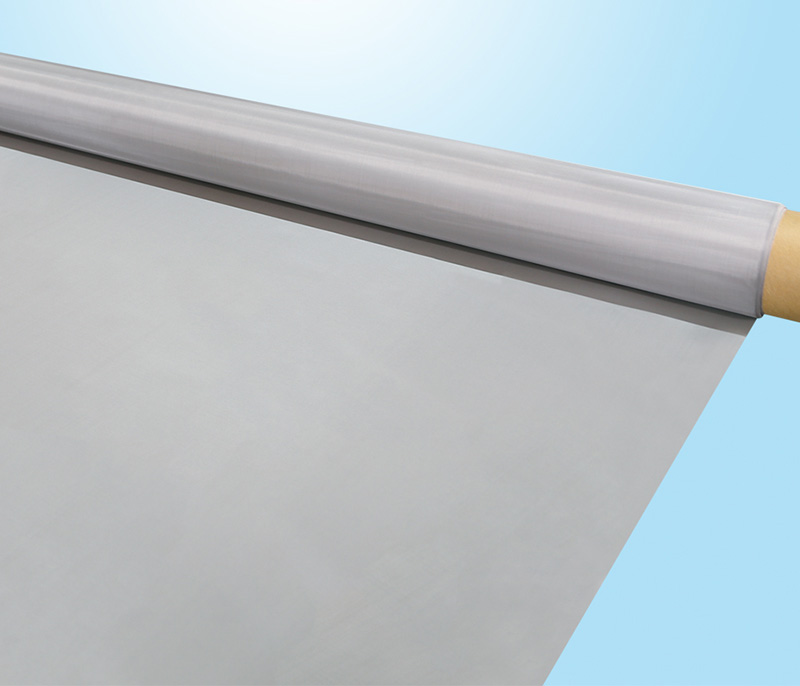

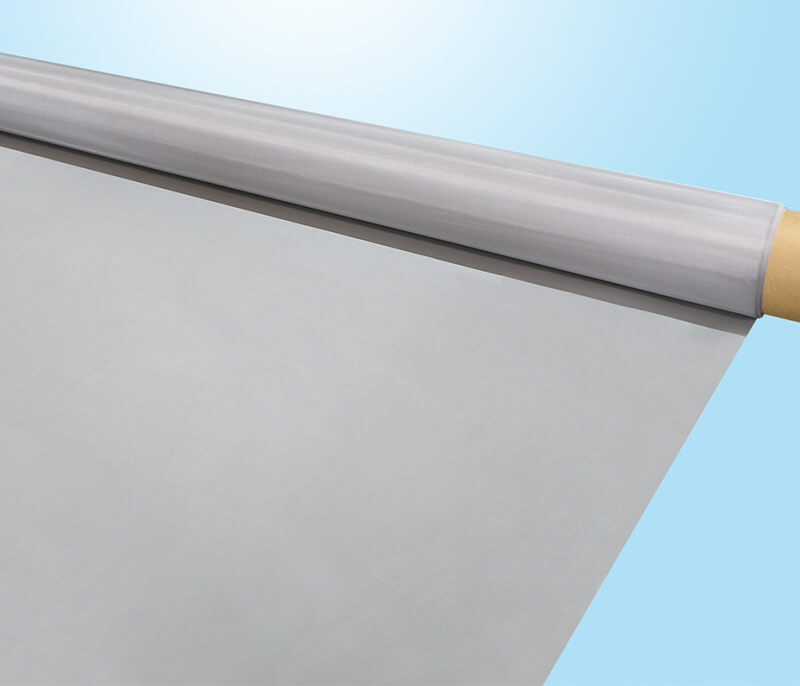

Stainless Steel Wire Mesh

Stainless steel wire mesh is made of stainless steel wire through warp and weft woven. 302 SS, 304 SS, 304L SS, 310 SS, 316 SS, 316L SS, 317L SS, 321 SS, 330 SS, 347 SS, 410 SS, and 430 SS is the material grades of our stainless steel wire mesh we produce. and our product mainly used for the filtration and screening of gas, liquid and solid, the separation of media and so on.

product description

what is stainless steel wire mesh?

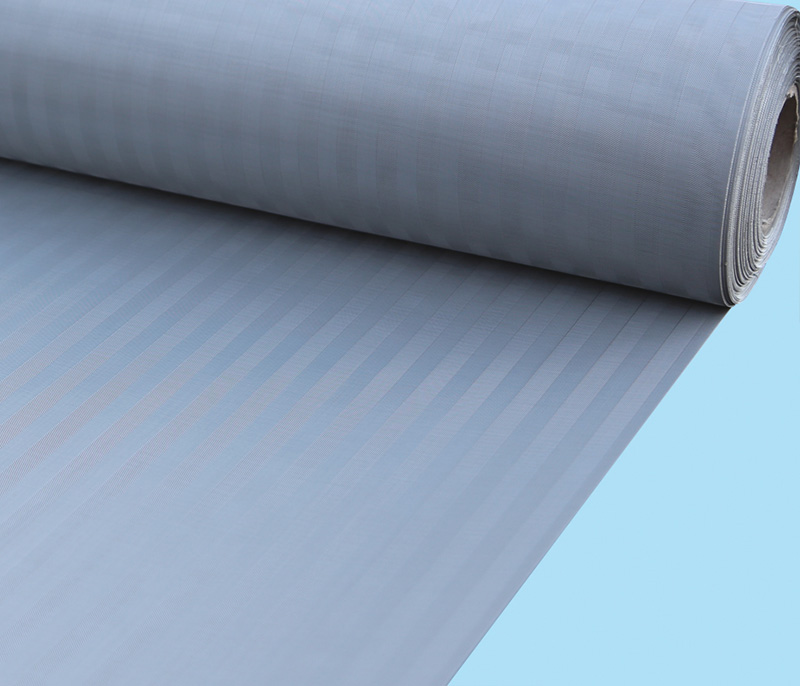

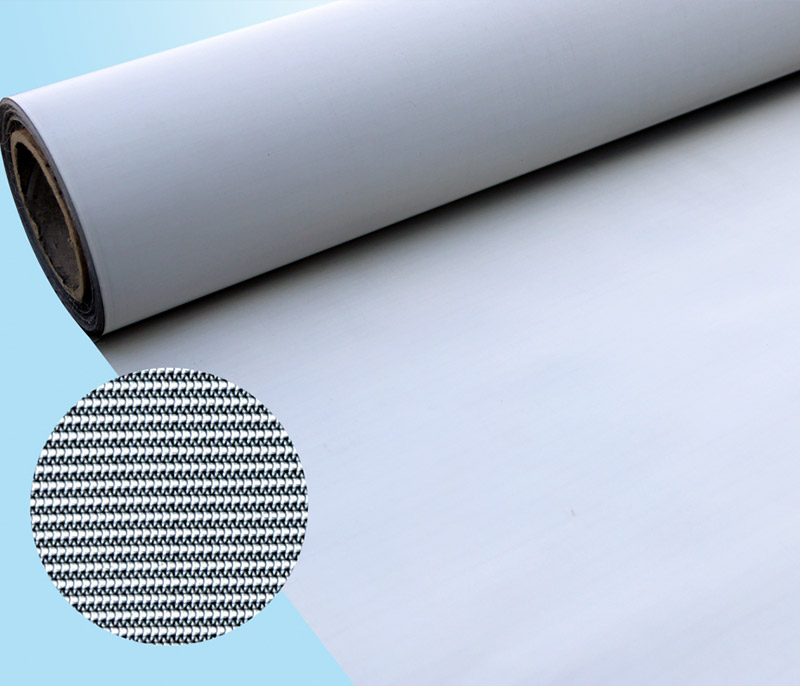

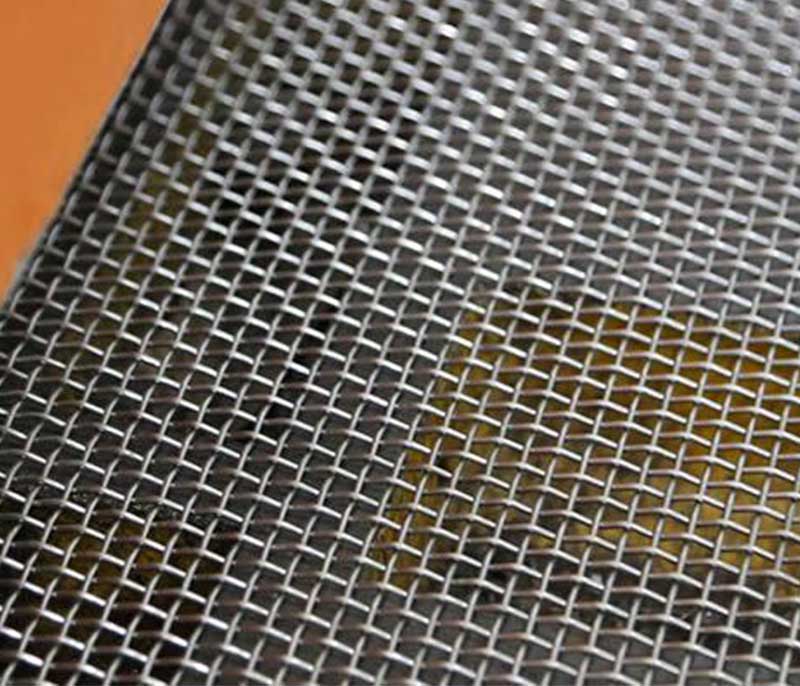

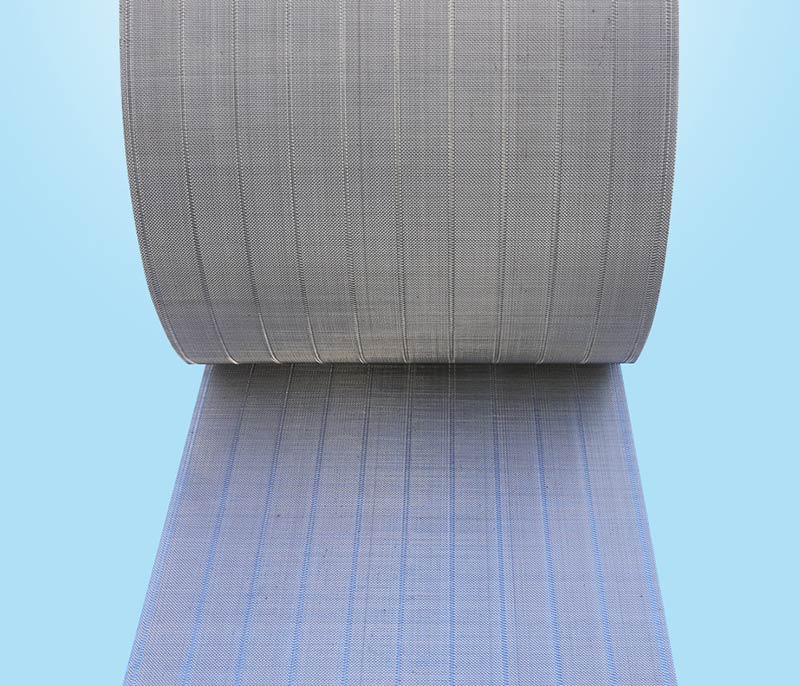

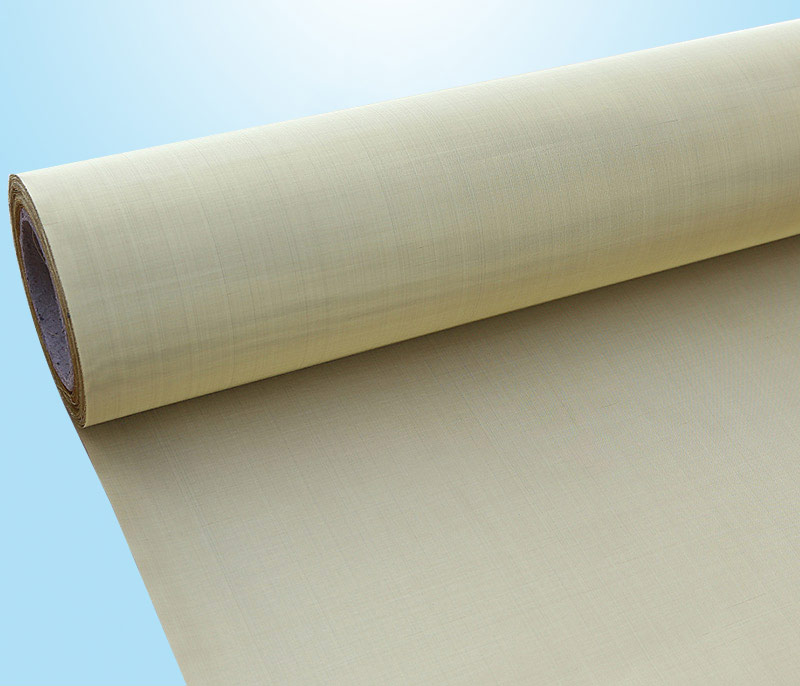

Stainless steel wire mesh is made of stainless steel wire through warp and weft woven. Mainly used for the filtration and screening of gas, liquid and solid, the separation of media and so on. With resistance for acid, alkali, high temperature and grind, it is widely used in industries like petroleum, petrochemical, automotive, new energy, food, pharmacy and others. According to the opening type and woven type, the stainless steel woven mesh can be divided into square mesh(plain weave, twill weave), dutch weave mesh(plain dutch weave, twill dutch weave, double warp dutch weave, reverse plain dutch weave, reverse twill dutch weave, optimized design). Square mesh: generally the wire diameter of warp and weft are the same, the mesh count of warp and weft are the same(rectangular mesh are not the same for warp and weft mesh count), weaving type can be divided into plain weave and twill weave. Dutch weave mesh: The stainless steel dutch weave mesh are also called dutch mesh, dutch cloth. It is made of high quality stainless steel wire. The main feature is that the wire diameter and density in the warp and weft direction are quite different, so the mesh thickness, filtration accuracy and the life time are obviously improved compared with the suqare mesh, specially on the filtration rate, it is not realized by the square mesh. The reverse dutch weave mesh is a special filter mesh, with warp mesh count obviously bigger than weft mesh count, and the warp wire diameter smaller than weft wire diameter. It is more difficult to weave than the plain dutch weave mesh, with high mesh strength, high filtration accuracy and high efficiency. The ducth weave mesh is mainly used in industries like aerospace, petroleum, chemical industry and others. It is suitable for filtration of plastic wire drawing machine, tape casting machine and film coating machine, such as plastic woven bags, plastic film, ink box, sewage treatment, etc. if need, welcome to contact us!

Stainless steel wire mesh characteristics

1. YKM stainless steel wire mesh product characteristics

2. Flat mesh surface, tightly weaved and uniform color

3. Uniform mesh opening, high and stable filtration accuracy

4. Accurate control of net weight per unit area to gram

5. Good formability mesh surface

6. Any length can be provided by continuous loading

7. With the most advanced weaving equipment in the industry

if need, welcome to contact us!

Stainless steel wire mesh advantages

YKM stainless steel wire mesh products including the special used high level square mesh, dutch weave mesh and normal stainless steel wire mesh used for industries like automotive, environmental protection, high-strength screening and protection, oil drilling and so on. The square mesh count ranges from 1 mesh to 635 mesh, dutch weave mesh can reach 3500 mesh, and diameter is from 0.015~8mm, the width can reach 6 m, and all can be produced according to the national standard, ISO, ASTM, DIN and other standards.

YKM's high-precision fine mesh products are produced by imported looms from Germany and Japan and new intelligent NC looms independently developed. The mesh are with the characteristics of good mesh flatness, high filtration accuracy and stable performance. Precision pressure filters, fuel filters and vacuum filters made by deep processing are widely used in industries like aerospace, petroleum, chemical, fiber, rubber, metallurgy, medicine, food and so on.

Additionally, stainless steel screen is strong and versatile enough to be installed into window and door frames in order to resist vandals and keep out insects. Government agencies and construction companies rely on stainless steel screen to provide protection to the interior of buildings from broken glass and debris caused by inclement weather. Panic room manufacturers install stainless steel screen and stainless wire mesh inside walls and doors to provide enhanced security from intruders. Stainless mesh also works well to guard roof gutters from tree leaves and other debris.

if need, welcome to contact us!

Stainless steel wire screen SPEC

Stainless steel square wire mesh

Stainless steel reverse dutch weave wire cloth

Stainless steel plain dutch weave

Stainless steel twill dutch weave

SS bolt mesh

if need, welcome to contact us!

Tags of Stainless steel wire mesh

fine stainless steel mesh australia fine stainless steel mesh brisbane fine stainless steel mesh canada fine stainless steel mesh filter fine stainless steel mesh melbourne fine stainless steel mesh nz fine stainless steel mesh perth fine stainless steel mesh uk fine steel mesh nz fine steel mesh roll fine steel mesh suppliers fine steel mesh uk wholesale stainless steel filter mesh stainless steel fine wire mesh fine stainless mesh metal fine mesh fine steel mesh sheet very fine wire mesh fine steel mesh screen fine wire mesh sheets ultra fine stainless steel mesh ultra fine wire mesh very fine metal mesh fine metal gauze fine metal mesh netting fine stainless steel screen super fine wire mesh stainless steel fine mesh sheet stainless fine mesh screen fine expanded metal super fine stainless steel mesh super fine metal mesh ultra fine metal mesh extra fine wire mesh very fine stainless steel mesh fine black metal mesh fine galvanised mesh fine steel wire mesh fine screen mesh stainless steel ultra fine stainless steel wire mesh fine metal mesh filter coarse stainless steel mesh fine stainless steel mesh sheet metal fine mesh screen filter media stainless steel vs wire mesh filter mesh stainless steel woven wire mesh filter pipe stainless steel mesh filter stainless steel mesh

related news of Stainless steel mesh screen

Will Destroying the Passive Film of Stainless Steel Wire Mesh Reduce Corrosion Resistance?

What are the Factors that Cause Aging When Using Stainless Steel Mesh Belt in Summer?

What is the Treatment of Stainless Steel Filter Rust?

What are the Technical Requirements for Welding Stainless Steel Filters?

Reasons for Broken Wires When Using Stainless Steel Wire Mesh?

How is the Stainless Steel Filter Screen Sprayed?

How to Avoid Clogging of Stainless Steel Mesh?

What are the Factors that Increase the Service Life of Stainless Steel Filter Elements?

What are the Main Methods of Processing Fine Stainless Steel Wire Mesh into Bag Filters?

How to ensure that the surface of Stainless Steel Mesh is smooth and shiny?

Do you know How to Distinguish Stainless Steel Wire Mesh and White Wire Mesh

if need, welcome to contact us! o

r you can directly mail or phone us, as follow:

tel: +86 318 7532 293 +86 318 7561 589

Fax:+86 318 7561 160 +86 318 7521 692

Mail:trade@yingkaimo.cn