What are the Technical Requirements for Welding Stainless Steel Filters?

May. 16, 2020

As a Stainless Steel Wire Mesh Supplier, share with you. With the high degree

of economic development, people's living standards are constantly improving.

Stainless steel products can be said to be a must-have product for thousands of

households, during which stainless steel filters are also more and more widely

used in the days. Well, we all know very well about the stainless steel filter

mesh. The stainless steel material can be divided into 5 categories. We commonly

use 304 and 316L stainless steel filters. Each brand of product requires welding

skills when welding. All of them are different. Let's take a look at the

specific technical requirements for welding products of different brands.

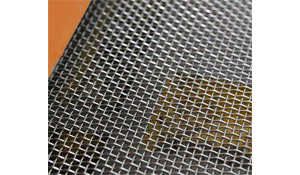

Gas Filtration SS Wire Mesh

The first type of austenitic stainless steel filter has better plasticity and less tendency to cold cracks, so no preheating is required before welding. In multi-layer welding, the inter-pass temperature should be avoided. Generally, it should be cooled to below 100 ℃ before welding the next layer; otherwise, the joint cooling rate will be slow, which will promote the occurrence of chromium carbide and constitute a decrease in intercrystalline corrosion resistance. In the case of extremely rigid workpieces, in order to avoid the occurrence of cracks, preheating before welding is necessary.

After welding austenitic stainless steel, in principle, no heat treatment is performed. As long as the welded joint is embrittled or its corrosion resistance is to be further advanced, the solution treatment, the stabilization treatment or the stress relief treatment should be selected as required. In addition, after welding austenitic stainless steel, in principle, no heat treatment is performed. As long as the welded joint is embrittled or its corrosion resistance is to be further advanced, the solution treatment, the stabilization treatment or the stress relief treatment should be selected as required.

The second type of hardened stainless steel filter has excellent weldability. It can be welded in any state of solid solution, aging and over-aging, and there is no need for preheating before welding and slow cooling after welding. However, assuming that equal strength welded joints are required, it is necessary to select the filler material with the same chemical composition as the base metal during welding. After welding, solid solution and aging heat treatment are required from the beginning. In addition, in order to soften and segregate the joints, it is necessary to strictly restrict the input of line energy when welding martensitic stack-hardened stainless steel by fusion welding. Electron beam welding, laser welding, and pulsed tungsten arc welding are preferred. Welding method; the hard standard should be used when selecting the resistance welding method.

Our company also has Gas Filtration SS Wire Mesh for sale, please contact us.