Low Carbon Steel Mesh

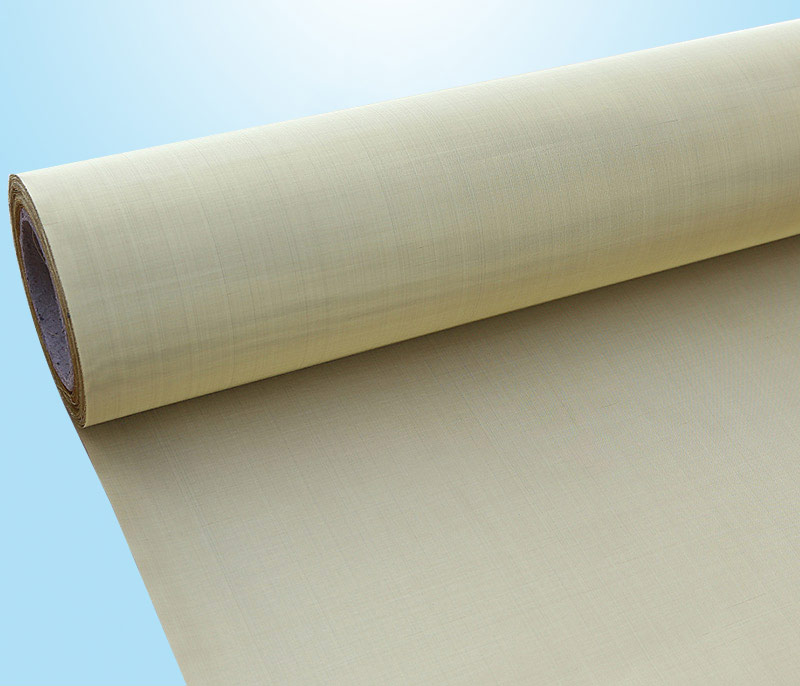

Low carbon steel mesh is a kind of wire mesh made of various carbon steel wires through warp and weft woven. The raw materials are generally Q295, but there are also high tensile carbon steel wire, copper coated steel and other materials.

product description

carbon steel mesh Detailed introduction of products

Low carbon steel mesh is a kind of wire mesh made of various carbon steel wires through warp and weft woven. The raw materials are generally Q295, but there are also high tensile carbon steel wire, copper coated steel and other materials.

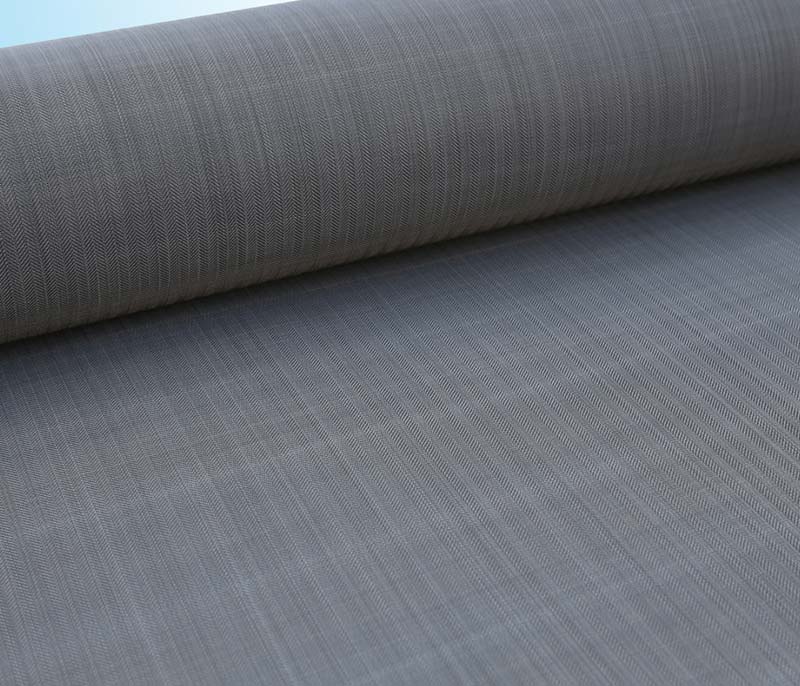

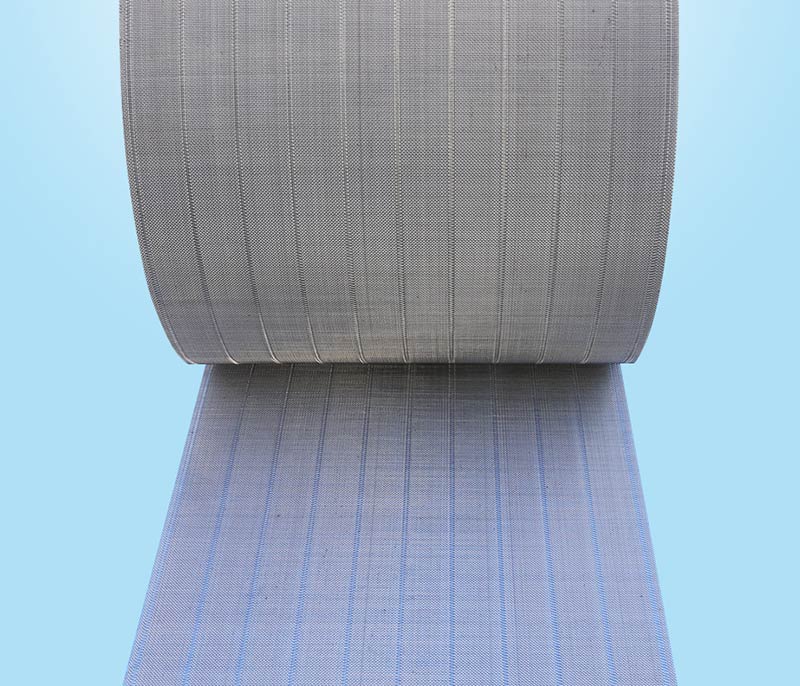

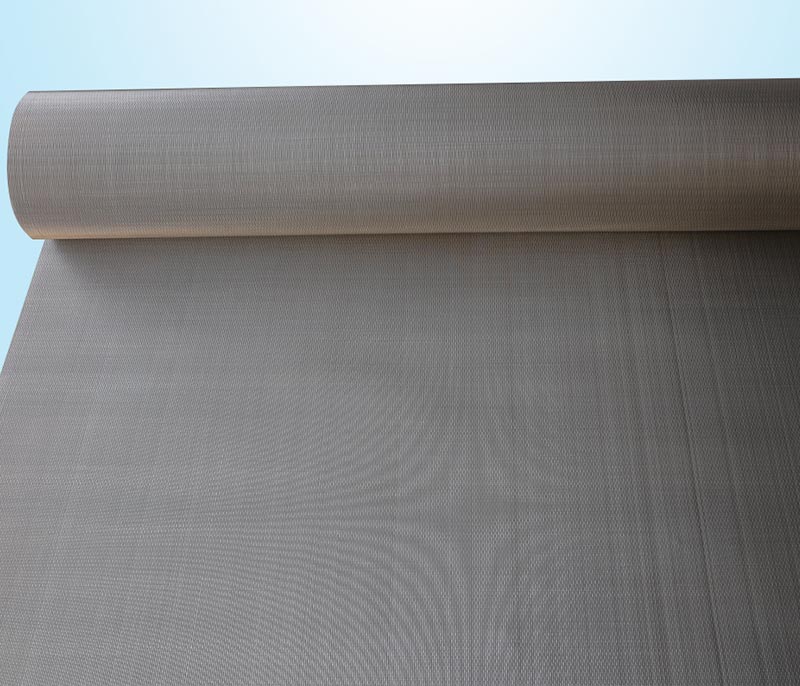

YKM low carbon steel mesh can be divided into plain weave square mesh, twill weave square mesh, plain dutch mesh, twill dutch weave mesh, herringbone mesh, reverse dutch weave mesh, etc.

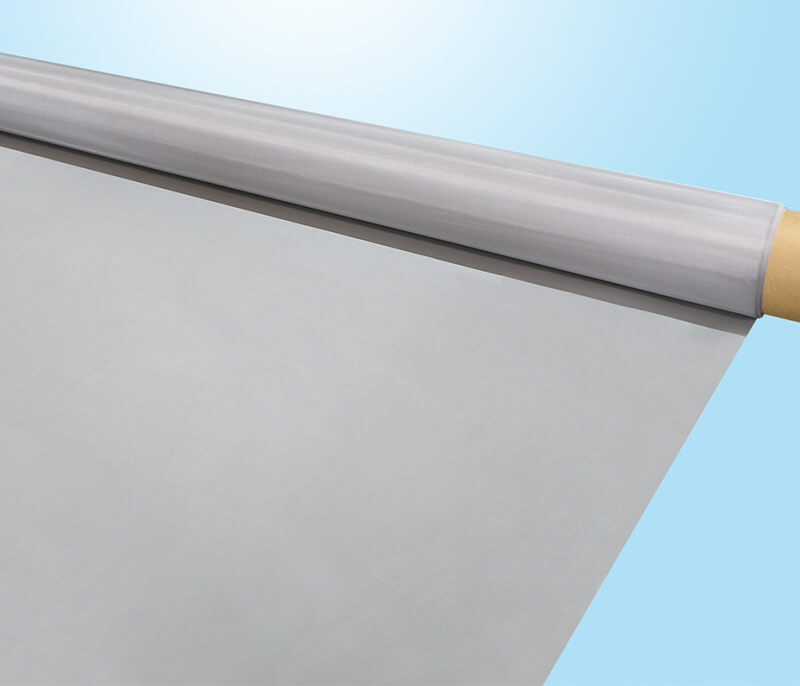

YKM is also specialized in the production of high quality low carbon steel, the raw mesh for epoxy coated wire mesh.

carbon steel mesh characteristics

YKM low carbon steel mesh product characteristics 1, Flat mesh surface, tightly weaved; 2, Uniform mesh opening, high accuracy; 3, Reliable filtration accuracy; 4, Long life time.

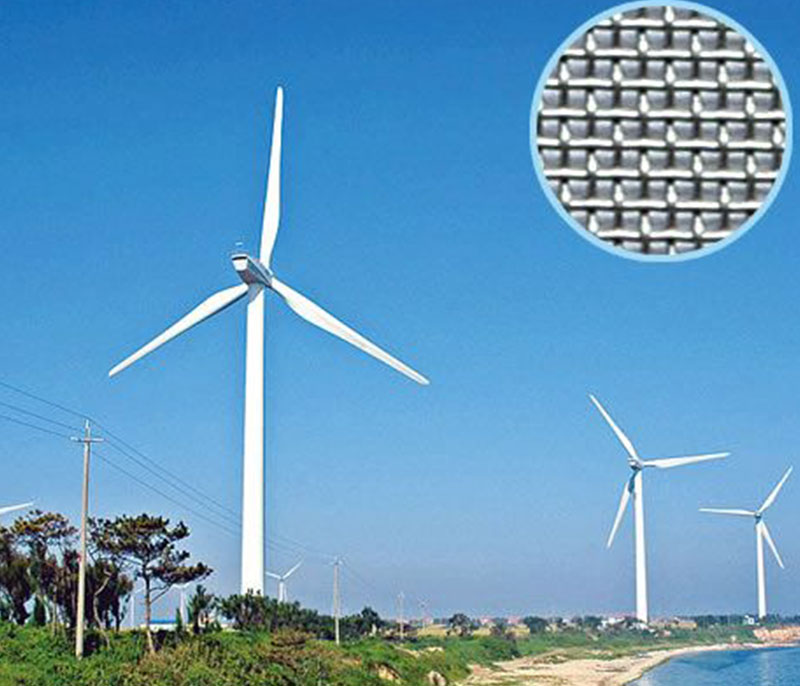

YKM low carbon steel wire mesh with the uniform mesh opening, flat mesh surface, long life time, wide use and so on. It is widely used in plastic industry, rubber industry, industrial filtration, petrochemical filtration, grain industry filtration. It is used to screen the granular powder, filtrate gas, and also used in various mould fields.

YKM has more than 20 years of experience in low carbon steel mesh production, with systematic and perfect quality control measures, our imported looms and domestic looms can meet the quality requirements of various product standards, YKM has advanced deep processing equipment which can provide customers with different sizes of mesh, mesh sheet, mesh cylinders and so on. All products are manufactured in accordance with international standards or customer requirements.

Carbon Steel Mesh is strong, which is why it has multiple uses in structural applications.

In addition to having high tensile strength, low carbon steel mesh can also expect high impact strength or toughness properties from the component. Both impact strength and tensile strength are properties relevant for structural applications. Economical pricing has also made this material popular with buyers and suppliers of low-carbon steel mesh in Mumbai. The fact that this alloy is readily available is also the reason for its growing popularity.

Unlike traditional austenitic steels that do not exhibit magnetic properties, mild steels are magnetic. This in turn makes the mesh suitable for applications that may require some magnetic force to work.

Although the properties of this steel are quite good, the use of heat treatment is not an option for low carbon expanded metal. While most steels thrive by using heat treatment, cold forming this alloy produces better results. Other benefits of using this alloy are good ductility and ductility, which enables manufacturers to produce mild steel woven mesh. Finally, because the alloys are easy to weld, they are suitable for applications that require welding in areas such as building and construction. Mild steel welded wire mesh can also be used as a component of piping systems or in the automotive industry.

Physical Properties of Low Carbon Steel Wire

Typical Density: 0.284 lbs/in3, 7.87 g/cm3

Resistivity (Typical): (ohm-cm@32°F, cold drawn): 0.0000143 - 0.0000174

Thermal Conductivity (Typical): BTU-in/hr-ft2-°F : 360

Average Coefficient of Thermal Expansion (Typical): µin/in-°F:

68 - 212°F: 6.5 - 7

Elastic Modulus: KSI

27.5 - 30.5 x 103 in stretch

Melting Temperature: 2600 - 2800 °F (1425 - 1540 °C)

Form

Outline, round, flat, square

Mechanical properties at room temperature

Features: Cold Drawn (Typical)

Ultimate Tensile Strength: 48 KSI min (330 MPa min)

Yield Strength: 41 KSI min (285 MPa min)

Elongation: 15% min

Attribute: tempered

These alloys can be cold worked into various states.

* Actual physical and mechanical properties depend on alloy.

Additional properties

Wire finish

XC - very clean. Annealed or annealed and cold rolled.

* For special finish requirements, please contact YKM.

heat treatment

Most of these alloys can be hardened by cold working and heat treatment.

carbon steel mesh SPEC

| Mesh(Mesh/Inch) | Guage(#) | Wire Dia.(mm) | Opening(mm) |

| 10 | 23 | 0.61 | 1.93 |

| 12 | 24 | 0.55 | 1.566 |

| 14 | 25 | 0.51 | 1.30 |

| 16 | 26 | 0.45 | 1.13 |

| 18 | 29 | 0.35 | 1.06 |

| 20 | 26 | 0.46 | 0.81 |

| 20 | 27 | 0.416 | 0.85 |

| 20 | 31 | 0.295 | 0.97 |

| 24 | 29 | 0.35 | 0.708 |

| 30 | 31 | 0.295 | 0.55 |

| 30 | 30 | 0.315 | 0.53 |

| 30 | 35 | 0.213 | 0.63 |

| 40 | 32 | 0.274 | 0.36 |

| 40 | 33 | 0.254 | 0.38 |

| 40 | 34 | 0.234 | 0.40 |

| 40 | 35 | 0.213 | 0.42 |

| 40 | 36 | 0.193 | 0.442 |

| 50 | 34 | 0.234 | 0.274 |

| 50 | 35 | 0.213 | 0.29 |

| 50 | 36 | 0.193 | 0.31 |

| 50 | 37 | 0.172 | 0.33 |

| 56 | 36 | 0.193 | 0.26 |

| 56 | 37 | 0.172 | 0.281 |

| 56 | 38 | 0.152 | 0.30 |

| 60 | 37 | 0.172 | 0.25 |

| 60 | 38 | 0.152 | 0.27 |

| 80 | 39 | 0.132 | 0.18 |

The width of the low carbon steel mesh can be range from 0.6m to 1.5m at any length. Other specifications can be produced per customers' request. We offer three kinds of carbon steel mesh from materials: low carbon steel mesh, high carbon steel mesh and oil tempered. From processing, we can supply three types: carbon steel hexagonal wire netting, carbon steel wire cripmed wire mesh and square woven carbon steel mesh. Low carbon steel crimped wire mesh used in mine, coal factory, construction and other industries | |||