Mesh Further Processing

Through knowledge of market and customer's demand in these years, YKM has accumulated rich experiences in mesh products deep processing, and self-designed slitting, plasma cutting,ultrasonic cleaning, pleating, welding and other kinds of processing equipment.

product description

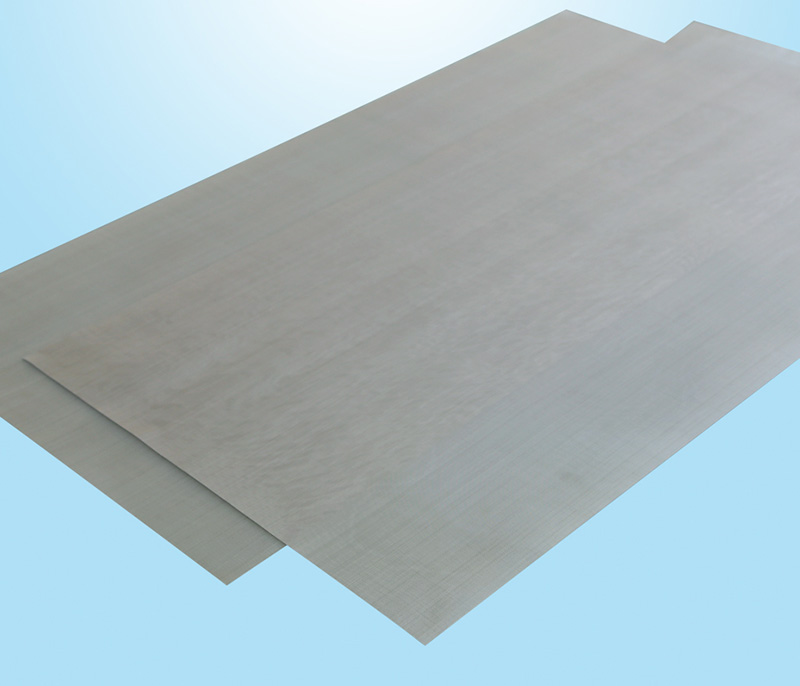

Through knowledge of market and customer's demand in these years, YKM has accumulated rich experiences in mesh products deep processing, and self-designed slitting, plasma cutting,ultrasonic cleaning, pleating, welding and other kinds of processing equipment. According to customers' request, stainless steel wire mesh, nickel wire mesh, low carbon steel wire mesh, galvanized wire mes, epoxy coated wire mesh etc. can be produced into mesh slits with different width and length, or various shapes of mesh discs, tolerance range can be accurate to ±0.1mm. YKM can supply mesh slits with the length up to 30000 feet, and make sure the stability of product quality and safety of the transportation at the same time.

Fabrication meshes of different sizes and shapes for various industrial uses

Woven mesh, also known as processed parts or molded parts, refers to the further processing of woven wire cloth into semi-finished products. Our fabric meshes are available in a variety of materials, meshes and weave structures. From simple cuts to complex and structurally efficient geometries, prefabricated meshes can be cut into square, rectangular, round or special shapes by cutting, punching and edging to meet the requirements of filter elements for filtration, separation and various industrial purposes specific requirements such as test sieves, melt and polymer filters, leaf filters and extruder filters.

Wire Mesh Processing Product specific form

After weaving the wire mesh, we start transforming it into the desired form. This process - including making and manipulating the mesh - is critical to producing the final product our customers order.

Depending on the final form, structure, performance and design requirements, a variety of post-knitting processes are available.

These include:

Coiling - A method of packing ground mesh into a flat spiral, suitable for shipping.

Folding and Layering - Used to construct knitted mesh mats for applications such as kitchen extractors or temper guards.

Hemming - Passing a continuous knitted net sock between the hem rollers makes it especially suitable for shockproof products.

Compression - Mesh is placed in a steel mold and compressed until it reaches the right size and density to create high-precision mesh rings and gaskets.

Spiral and Milling – When a continuous length of compressed web is required, the helical web is placed in individual web sleeves and drawn through a rolling mill

We manufacture wire mesh and wire mesh products to meet your individual requirements for function and form, from simple to highly complex.

YKM also can design and manufacture mesh tube, mesh bowl, special-shaped mesh discs, spots welding discs and other further processing mesh products.