How is the Stainless Steel Filter Screen Sprayed?

Apr. 29, 2020

As a Petroleum Wire Mesh Manufacturer, share with you. The stainless steel

filter has now become a leader in the transportation profession, and it is loved

by a wide range of users. The filter must be sprayed during the application

process. As long as this is the best way to protect it, then about the spraying

of the stainless steel filter What are the first and foremost solutions? Let ’s take a closer look.

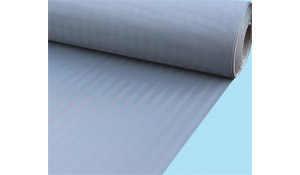

Fine Stainless Steel Wire Mesh

Pretreatment of stainless steel filter screen, in order to make the coating film have strong adhesion, not easy to fall off, and long life, it is necessary to pretreat the surface of the stainless steel filter screen before spraying. Dry coating is divided into physical dryness and chemical dryness according to the nature of the coating. The pretreatment of the Great Wall filter is very tied, and spraying is also a process of demand, which is divided into three processes, the first step is to pretreat the predecessor, then the spraying, and finally to be boring. The order of the three processes cannot be interchanged. There are more than ten kinds of paints such as oil paints, natural resins, epoxy resins, phenolic resins, etc., which can be selected according to the actual situation.

Dry stainless steel filter screen To make the coating function excellent, strong and wear-resistant, it must be used after it is fully dry. Different stainless steel filter pretreatment methods are different. Spraying methods include manual, active, electrostatic, electrophoresis and other methods, which can be selected according to the batch size and shape of the Great Wall filter.

Spraying varies according to the type, function and curing premise of the coating, and the spraying process and method are also different. Users can choose the shape, size and batch size of the stainless steel filter. In practice, for rapid drying, solvent-volatile coatings or heat-curing coatings are often used, and aspiration can be achieved through natural drying or simple drying processes. Iron and steel parts are treated primarily by degreasing, derusting, phosphating, etc. Commonly used water-based cleaning liquid decontamination and degreasing, mechanical or chemical derusting, phosphating is to immerse parts in acidic diluent (density 1 ~ 1.1, PH = 1 ~ 3), the response will occur at the interface between the two.

Speaking of the relevant knowledge of stainless steel filters, I believe that everyone is not unfamiliar, its application has been widely used day by day, and a lot has been described, so apart from these, do we know what we need to pay attention to its use?

1. The best way to put different specifications and different types of stainless steel filters together is to use the glue connection method.

2. The running speed of the stainless steel filter screen should not generally be greater than 2.5 m / s. Low-speed materials should be used for materials with large abrasion and the use of firm plow-type unloading installation.

3. The type, layout, specifications, and number of layers of stainless steel filter should be selected reasonably according to the conditions of use.

4. During transportation and storage, the stainless steel filter should be kept clean to prevent sunlight exposure or rain and snow immersion, be prepared to fight against acids, alkali oils, inorganic solvents and other substances, and install one meter away from the heat.

Our company also has Fine Stainless Steel Wire Mesh for sale, please contact us.