Introduction of brass mesh environmental protection polishing process

Jun. 07, 2022

Introduction of brass mesh environmental protection polishing process

1. Tools raw materials

a、Brass mesh; b、SanLy 202C cleaning agent; c、SanCy 701(A) polishing solution; d、SanCy 701(T) stripping agent; e、DunHua 680 passivation solution; f、gel frame.

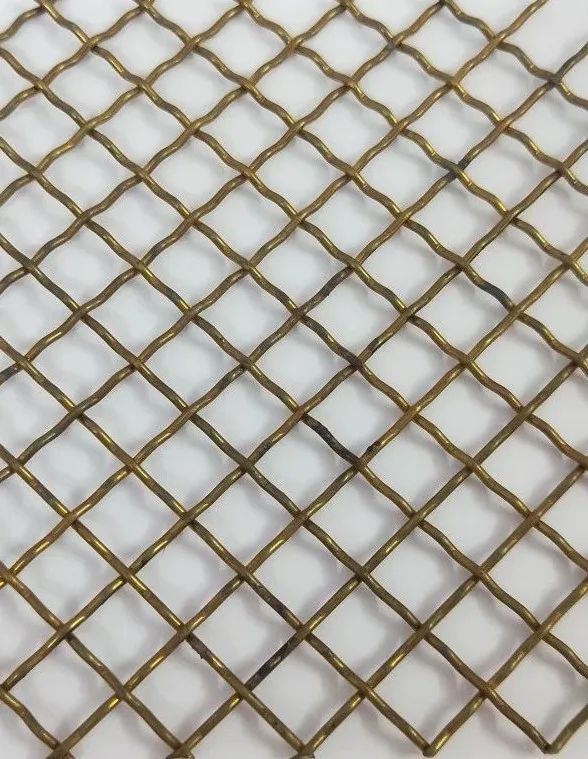

Before treatment

2. Process flow

Step 1:Preparation

Cleaning agent: SanLy 202C(5%)+H₂O(95%)

Polishing solution: SanCy 701A(5%)+H₂O₂(30%)+H₂O(65%)

Release agent: SanCy 701T(10%)+H₂O(90%)

Passivating agent: DunHua 680(10%)+H₂O(90%)

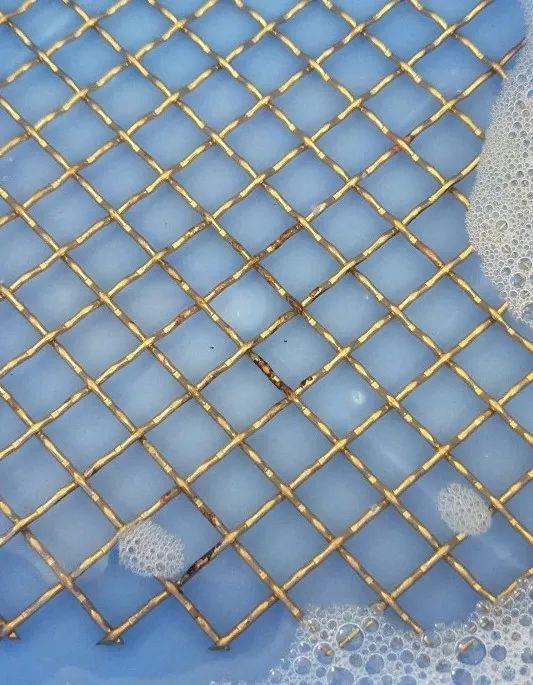

Step 2: Cleaning

Put the brass mesh workpiece into the prepared SanLy 202C cleaning agent for cleaning treatment for 3~5min.

Step 3: rinsing

Put the cleaned brass mesh workpiece into tap water and rinse.

Step 4: Polishing

Put the cleaned brass mesh into the prepared Sancy 701(A) polishing solution, polishing time 1~3min, and wait for the formation of uniform brown film on the surface of the brass parts.

Step 5: Rinsing

Put the polished brass mesh into the tap water and rinse.

Step 6: decontamination

Put the rinsed brass mesh into the prepared Sancy 701(T) for de-film treatment, generally soak for 5~10 seconds for the film layer to fall off.

Step 7: Rinsing

Put the brass mesh into tap water and rinse.

Step 8: Passivation

Put the cleaned brass mesh into the prepared DunHua 680 for passivation treatment for 5min.

Step 9: Rinsing

Put the passivated brass mesh into tap water and rinse.

Step 10: Drying

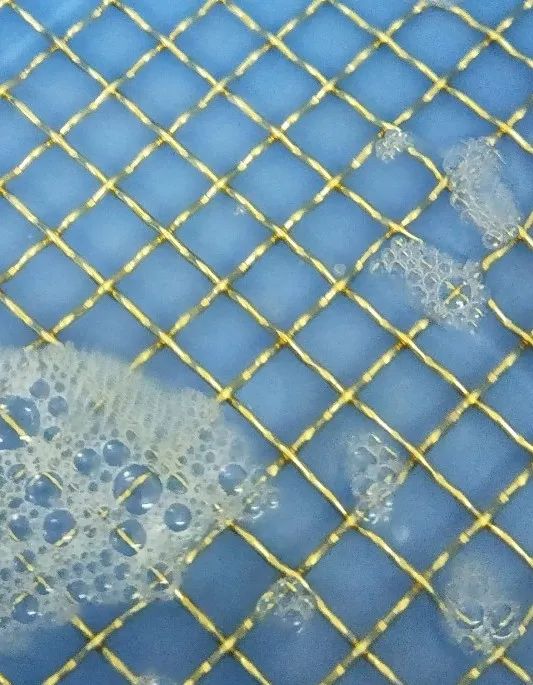

After treatment