What is Nickel Mesh?

Oct. 31, 2019

As a Nickel Mesh Manufacturer, there is some information you want to share with you. Nickel wire mesh production can be produced according to customer needs and customer requirements for wire diameter and mesh. Pure nickel filter is mainly used in petroleum, chemical, aerospace and other industries.

Nickel wire knit net: Nickel wire knit net is also a kind of nickel wire mesh. It is a vapor-liquid filter net, also called pure nickel wire foam net, pure nickel wire froth net.

Pure nickel wire knit net is a special crochet process made of wire mesh. It is widely used in wire mesh demister in special production environment, oil and gas processor, internal combustion engine filter, dust filter, etc. The general specification of mesh width is 25mm- 600mm. Mesh size, filtration accuracy can be produced according to customer requirements.

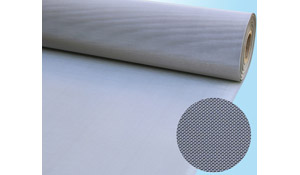

Nickel Mesh

Nickel mesh is characterized by corrosion resistance, acid, and alkali resistance, and is generally used for screening under strong acid and alkali conditions and for gas, liquid filtration and other media separation.

The main weaving process of nickel mesh is plain weave, twill weave, and mat weave. The main size of plain weave is 1 mesh - 200 mesh, and the weaving of plain weave is characterized by the same density of warp and weft per inch.

The main specification of the twill weave is 1 mesh-220 mesh. The tension of twill weave is better than that of the plain weave. The main specification of the mat weave is 45 mesh-800 mesh, and the filtering precision can reach 20um. It is a plain weave mesh and a twill weave mesh. Unable to achieve filtration accuracy.

Then is the nickel mesh resistant to corrosion?

Nickel Mesh is mainly used for screening under acid and alkali conditions and for gas, liquid filtration and other media separation. Among them, weaving nickel mesh has five methods: plain Dutch weave, twill weave, plain weave, twill weave, and reverse Dutch weave. The specification of nickel mesh is 1 mesh - 330 mesh.

1. Plain nickel mesh: The main feature is that the warp and weft wire diameters are the same, which is the most common weaving method.

2. Pure nickel-nickel square mesh: Nickel square mesh is suitable for petroleum, chemical, chemical fiber, rubber, tire manufacturing, metallurgy, medicine, food and other industries. Nickel wire is woven into various specifications of mesh and cloth, with good acid and alkali resistance. , high-temperature resistance and other properties.

3. pure nickel dense mesh

Material: Nickel wire weaving: Twill weave nickel dense mesh, plain weave nickel dense mesh, bamboo flower weaved nickel dense mesh

Uses: used in aerospace, petroleum, chemical, and other industries. Performance: It has the characteristics of stable and fine filtration performance.

Nickel wire mesh is a filter mesh woven from nickel wire. The main common nickel wire is N4 and N6. The N6 material mainly contains more than 99.5% nickel. The nickel wire mesh used in N4 material can be made of nickel wire of N6 material. Network instead.

Nickel wire mesh has excellent corrosion resistance, acid, and alkali resistance, and is mainly used for screening under strong acid and alkali conditions and gas, liquid filtration and other media separation. Our company also has N4 Nickel Mesh on sale, welcome to come to consult.