Stainless Steel Wire Mesh is susceptible to the environment

Oct. 23, 2019

When we use any product, we are affected by some environmental factors. For example, when using metal, we are susceptible to thermal expansion and contraction. Therefore, when we use Fine Stainless Steel Wire Mesh, it is very susceptible to thermal expansion and contraction, and sometimes it is unavoidable. Therefore, as a Stainless Steel Wire Mesh Supplier, we will focus on explaining the mesh belt. The phenomenon of thermal expansion and contraction is expected to help you understand some skill operations when using Stainless Steel Wire Mesh.

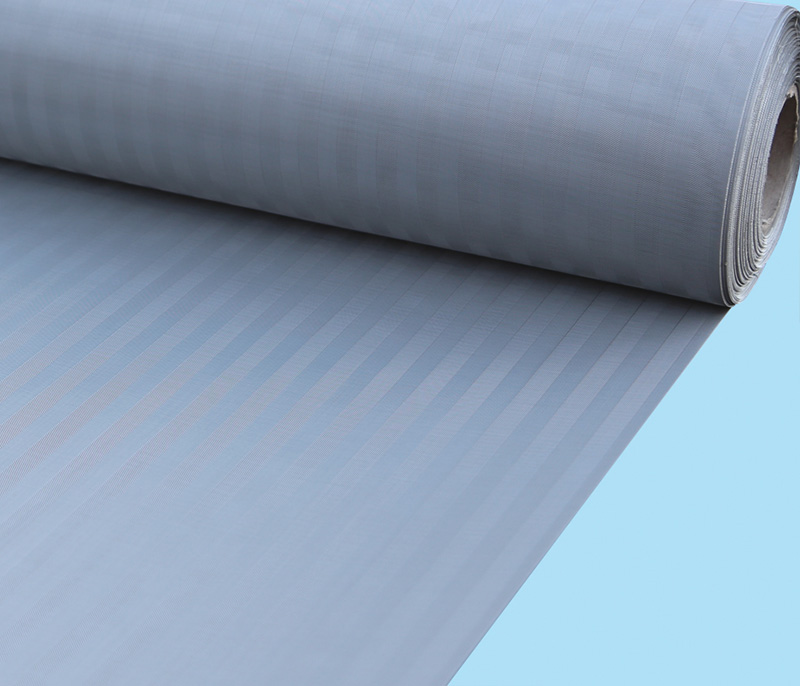

Fine Stainless Steel Wire Mesh

In general, ordinary mesh belts work hot and brittle at high temperatures, as does Stainless Steel Wire Mesh. Stainless Steel Wire Mesh is the heat generated by friction during work. Due to the difference in the manufacturing process, the thermal expansion coefficient of Stainless Steel Wire Mesh is different. When different materials are welded together, there is a possibility of thermal fatigue. When the ambient temperature exceeds 400 ° C, the expansion of the belt conveyor between the whole machine caused intermittent reduction should also be fully considered. Of course, there is a point that when Stainless Steel Wire Mesh is exposed to inert materials, it will cause undesirable results. First, the Stainless Steel Wire Mesh parts will become finer and finer, resulting in accelerated wear. The rust on the Stainless Steel Wire Mesh parts is also Will affect the flexible rotation of the roller. I hope the above introduction will help you to use Stainless Steel Wire Mesh.

In order for our work to be carried out smoothly, there are usually many issues to be aware of before using the product, as is the application of the Stainless Steel Wire Mesh. Here, in order to better help you, Shanghai Haoyin Machinery professional and technical personnel should pay attention to the following matters for Stainless Steel Wire Mesh:

(1) The tension of Stainless Steel Wire Mesh should not be too large in use, and it should work under the minimum initial tension under the premise that the transmission gear does not slip and the receiving point does not excessively sag.

(2) Different types and different specifications of Stainless Steel Wire Mesh shall not be connected together in the same machine.

(3) Generally, the conveyor is required to be operated to prevent the motor from overloading and the Stainless Steel Wire Mesh from slipping; before the shutdown, the materials on the Stainless Steel Wire Mesh should be completely discharged except for special cases.

(4) The boot sequence is to open the last conveyor (Stainless Steel Wire Mesh), then open in order, and finally open the receiving conveyor. The order of a shutdown is the reverse of the boot sequence.

Stainless steel wire mesh used:

1. Used for screening and filtration under acid and alkali environmental conditions, oil industry for mud network, chemical fiber industry, sieve screen, electroplating...

2 For mining, petroleum, chemical, food, pharmaceutical, machinery manufacturing and other industries, our company has Stainless Steel Mesh For Petroleum.

3: It is used for screening and filtration under acid and alkali environmental conditions. The petroleum industry is used as mud net, chemical chemical fiber industry for screening, electroplating industry as pickling net. Our factory can design and produce various types of products according to user needs.

Stainless steel wire mesh features:

Good acid resistance, alkali resistance, and rust resistance;

High strength, strong tensile, toughness and wear resistance, durable;

High-temperature oxidation resistance, 304 stainless steel screen nominal temperature tolerance is 800 degrees Celsius, 310S stainless steel screen nominal temperature tolerance up to 1150 degrees Celsius;

Normal temperature processing, that is, easy plastic processing, diversifying the use possibilities of stainless steel screens;

High finish, no surface treatment, easy maintenance.