What are the Reasons For The Spray Paint of the Stainless Steel Wire Mesh to Fall Off?

Aug. 19, 2021

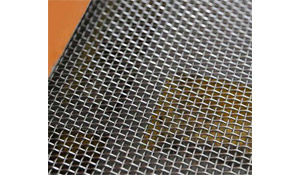

As a Stainless Steel Wire Mesh Supplier, share it with you. In the process of using stainless steel wire mesh, when there is no appearance conflict, only simple filtration or protection, because long-term use in nature will make the appearance not smooth, dull or rust (stainless steel will also rust), so consider stainless steel. The process of painting the surface of the screen, but some customers will say that the stainless steel screen is easy to fall after painting.

Gas Filtration SS Wire Mesh

Now let's analyze the reasons why the spray paint of stainless steel wire mesh is easy to fall. The temperature is not good; the use of good quality powder should also pay special attention to. The powder will not be fully melted at high temperature before it is formed, and it will not be fixed well on the mesh.

The quality of the powder is not good; the main reason is that the particle size of the powder is different. In this way, the powder is not sufficiently melted at a high temperature, so its adsorption force will naturally become smaller. The quality of the stainless steel wire mesh; the most important thing is that the stainless steel wire mesh must be clean and hygienic before spraying, and there must be no dust or grease on the outside. If the mesh is not hygienic, it will also affect the powder.

The final adsorption force assumes that there are bleaching agents and various acids attached to the surface of the stainless steel wire mesh, which is easy to rust. How to maintain the stainless steel wire mesh in use can improve its life span. We all know that stainless steel is not rusty, which is why people like it. We also have Gas Filtration SS Wire Mesh on sale, welcome to contact us.