How to distinguish between stainless steel and brass

Nov. 26, 2021

Stainless steel and brass are metal alloys used in lighting fixtures, door hardware, picture frames, candlesticks and other decorative items. Metal formulators produce decorative brass statuettes dating back to ancient times using formulas consisting primarily of copper and zinc. There are many different ways to make decorative items from stainless steel, but in all varieties, the main components are iron and chromium.

Stainless steel and brass are widely used in construction, transportation, mechanical engineering and plumbing. But which one of them is better? Or is it necessary to compare them? Let's find out the truth about the "brass vs. stainless steel" dilemma.

Getting to know stainless steel

Unlike brass, stainless steel has a silvery-white appearance and is often polished to give it a brilliant shine. Despite the name, decorative stainless steel items may tarnish due to corrosion or rusting - usually caused by defects in the manufacturing process. This discoloration may give stainless steel a brass-like appearance. An easy way to confirm that the metal is stainless steel is to press a magnet against its surface; unlike brass, most stainless steel varieties are highly magnetic.

Because of their hygienic qualities, brass products again overlap with steel in the medical and surgical fields. Another popular use for brass is the manufacture of musical instruments, as well as fishing rods and pins, sanitary fittings, etc. Steel is superior to brass in terms of accumulated stress because it has a longer fatigue life compared to brass or other metal products. Both brass and steel are easy to use for welding and brazing.

Getting to know brass

Brass products are available in a variety of colors, ranging from deep yellow to reddish gold. Thin brass items such as cymbals or vases have acoustical properties that produce resonant ringing when struck by drumsticks or mallets. Decorative brass is often coated with lacquer to protect the outer surface from tarnishing due to oxidation. Oxidation produces an antique brass color, adding a dark gray or green cast to brass, which is often preferred by home decorators.

Brass is a tensile metal with a high bending capacity. It is used to make bearings, valves and moving parts because it does not break easily. In contrast, steel is difficult to cast and is hard to work on small machines. Brass is far more capable on machines than steel, which is only 40 to 50 percent efficient on machines. Compared to steel, brass is a good conductor of heat and energy. The overall efficiency of steel and brass scrap can also be compared. Brass scrap does not lose its value and cost, has minimal impact on its efficiency and is a good material for recycling.

Brass has some significant advantages, for example it is the preferred choice for industrial and agricultural applications. Compared to steel alloys, brass is corrosion resistant and less prone to rusting, but both elements may react with different corrosives. Due to its high corrosion resistance, brass is used for petroleum products as well as for hot or cold water transport in industrial or residential systems. The tensile strength of brass also overlaps with that of carbon steel. The strength of brass makes threaded parts stronger.

Brass is nickel plated to prevent discoloration and is used for surface hardening of products and for decorative purposes. Steel is chromium plated to make stainless steel. Steel wire is also plated with brass for use in steel belt tires to promote adhesion to rubber. Steel becomes brittle at low temperatures, but brass can withstand extreme weather conditions. Brass comes in a variety of shades from gold to silver and is malleable enough to be used for jewelry making and decorative purposes, such as for lamps and lampshades. Architects use brass to decorate or renovate buildings because it is available in a wide range of colors and shades.

Composition and properties

The best way to distinguish brass from stainless steel is to know their composition. Brass is an alloy of copper and zinc, while steel is an alloy of iron, carbon and chromium. By their base metals alone, you can easily distinguish which has the right properties for a particular application. For example, when it comes to corrosion resistance, iron is dwarfed by copper. In fact, iron is the metal that causes ferrous metals to rust quickly.

In short, brass is generally more resistant to corrosion than stainless steel. Although the addition of chromium to steel has a significant impact on its ability to resist rust, it is still somewhat susceptible to corrosion.

In terms of electrical and thermal conductivity, brass is 15 times more conductive than stainless steel. It also has a higher coefficient of thermal expansion, which makes it ideal for applications involving extremely high temperatures, including furnaces and engines.

In terms of manufacturing costs, there is no significant difference between brass and steel, although steel is more difficult to machine than brass. After all, brass is known for its machinability, which is why it is the metal of choice for applications that require small, precise metal parts, so steel doesn't stand a chance.

Conversely, stainless steel has a higher tolerance to petroleum products and many acids than brass, and can be passivated in citric or nitric acid solutions. Certain grades of stainless steel are also superior to brass in more aggressive marine environments such as fast-moving currents.

Cleaning decorative brass and stainless steel

Once you have determined whether the object is brass or stainless steel, you can choose the best method of cleaning and maintenance. You can find products designed for the specific cleaning needs of brass and stainless steel at hardware stores and most large grocery stores. Most brass can be cleaned with a few drops of ketchup on a damp kitchen rag, and you can usually restore the shine of stainless steel by wiping with a rag soaked in diluted dish soap.

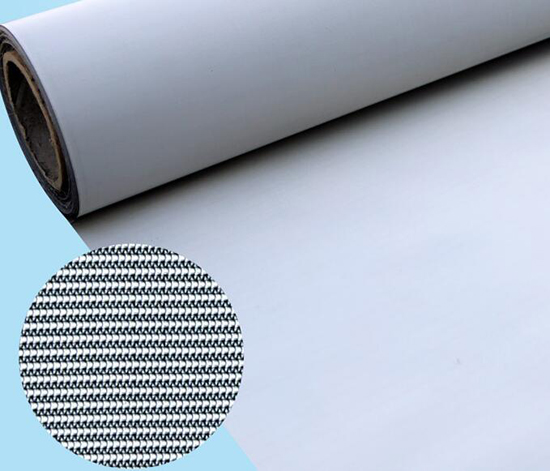

About Stainless Steel Wire Mesh

Stainless steel wire mesh is commonly used as safety mesh, foundation mesh or outer mesh for construction, transportation or water conservation projects. Due to the use of stainless steel as the metal mesh material, it has corrosion resistance, high strength and good flexibility. Stainless steel wire mesh as construction fence mesh is not easy to be cut by hard objects. It can adapt to the harsh outdoor working environment and can be reused. One investment can be used many times, which reduces the cost. When stainless steel wire mesh is used in water conservancy projects, it can effectively prevent the embankment from being washed by water and causing the embankment to collapse, ensuring the safety of the project.

Stainless steel wire mesh is woven from stainless steel wire, nickel wire, brass wire and other materials. Weave: plain, twill, (plain/twill) mat dense weave. There are stainless steel welded wire mesh, rolled wire mesh, perforated wire mesh, steel mesh, and mining sieve mesh. Mesh count: 1 mesh-2800 mesh. Material: SUS302, 201, 304, 304L, 316, 316L, 310, 310S, etc.

Stainless steel wire mesh is used for sieving and filtering under acidic and alkaline environmental conditions. Petroleum industry for mud mesh, chemical fiber industry, as sieve filtration, electroplating, used in mining, petroleum, chemical, food, pharmaceutical, machinery manufacturing and other industries. It is used for sieving and filtering in acid and alkaline conditions, for mud mesh in petroleum industry, for sieve mesh in chemical fiber industry, for pickling mesh in electroplating industry, and our factory can design and manufacture various products according to users' needs.