What are the advantages of epoxy coated wire mesh?

Oct. 21, 2021

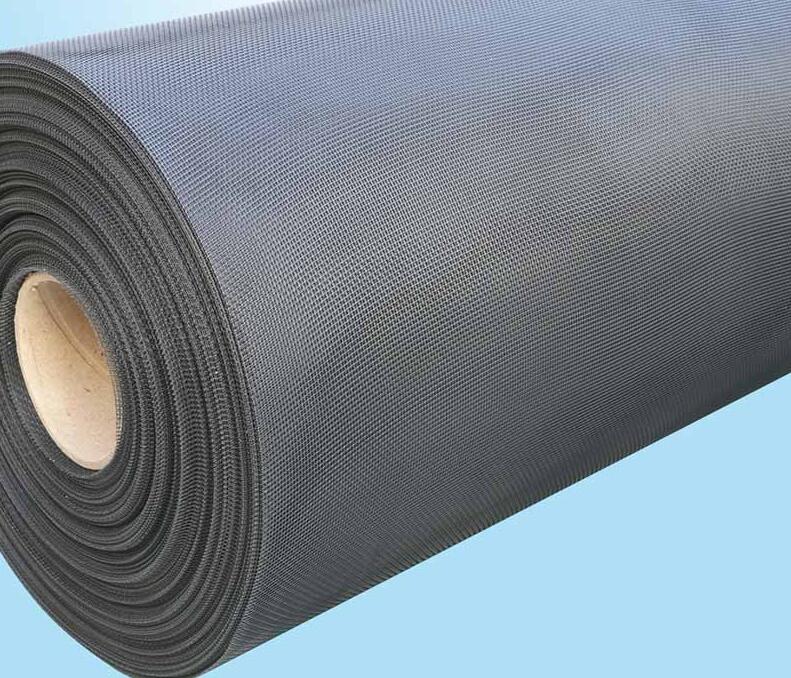

Epoxy coated wire mesh

The manufacturing process of epoxy coated wire mesh is to use the principle of electrostatic spraying to adsorb environmentally friendly epoxy resin powder onto the surface of the wire mesh woven from different metal wires. After a certain time of high temperature curing, the epoxy resin powder melts and covers the substrate. A dense protective layer is formed on the surface of the mesh, allowing the product to be safely exposed to harsh and corrosive conditions such as seawater, de-icing salts and solvents.

Epoxy coated wire mesh is trusted for its affordability and diverse constructability. Epoxy powders are available in indoor and outdoor types, and special powders can be custom developed to meet customer requirements. The base material mesh usually includes mild steel mesh, aluminum alloy mesh and stainless steel mesh.

●Epoxy mesh manufacturing standard: GB/T 17492-2019 ●Weave pattern: Flat wave rough edge/flanged edge

Features of epoxy coated mesh

After epoxy coating, the metal mesh interweaving points are fixed, warp and weft are vertical, the mesh is uniform, not easy to loosen and deform, the support for filter paper is strengthened, the mesh is soft and easy to use. Folding and forming; uniform coating thickness and uniform color.

Uses and classification of epoxy coated mesh

According to different uses, epoxy mesh can be divided into industrial epoxy mesh and civil epoxy mesh.

Industrial epoxy mesh mainly refers to aluminum alloy epoxy mesh and low carbon steel epoxy mesh, which are mainly used as filter element support mesh, also called hydraulic filter element protection mesh and hydraulic filter element metal mesh.

Civil epoxy mesh mainly refers to stainless steel epoxy mesh, which is mainly used as security window screens in high-grade residential and commercial buildings.

Epoxy coated mesh can be used to reinforce airport runways, roads and parking lots, bridges, marine environments, stadiums, and concrete pipes.

Advantages of our epoxy coated mesh

►Surface treatment powder with low temperature fast curing oil resistant matting resin paint (160℃/90s) and low temperature curing weather resistant matting polyester paint (160℃/90s).

►Weathering corrosion resistance, according to ASTM B117-09 salt spray test standard, continuous test 96H coating surface unchanged, suitable for harsh environment air filter and outdoor environment.

►The net surface is square and not deformed after coating, the surface is flat and the maximum undulation height of the platform is ≤10mm. the powder coating volume is controlled at 20-35g/㎡, the interlacing point is moderate.

►It has strong adhesion and can pass impact test, scratch test and fatigue resistance test. It has high resistance to bending and can pass the steel bar folding with 1mm radius of curvature without cracks on the surface.

►The industry selects high quality steel and drawing and annealing process, combined with new weaving process, the mesh surface is soft and the elastic modulus is low.

After coating, it is easy to fold and shape. After processing the product, the warp and weft wires are firmly combined and not easy to fall off. The edges will not fall off after slitting. The adhesion of coated interwoven points can reach 0.7kg.

►It is resistant to oil immersion and corrosion. It can pass the test of different brands of hydraulic oil media around the world at different temperatures and times. There is no change in the surface of the coating. It is suitable for high temperature and high pressure special hydraulic filtration products.