The main differences between galvanized steel and stainless steel

Feb. 09, 2022

Whether you're talking about the structural or aesthetic elements of architecture, steel is one of the most important innovations of the modern world. Stronger and more resistant to all forms of degradation than iron, steel has been the catalyst for everything from the bones of high-rise buildings to unique and eye-catching design components.

Understanding the differences between the various types of steel available can help you make the most informed and positive choices. Let's take a quick review of what steel really is to help determine the differences between galvanized and stainless steel.

Galvanized steel is common in a variety of construction applications.

Forging an understanding of steel

"Steel is an alloy consisting of two key base components: iron and carbon."

Steel is an alloy consisting of two key base components: iron and carbon. An alloy is simply a combination of two or more base metals or base metals and elements. Alloys can provide a variety of important benefits in many different applications, from improved rust resistance to the manufacture of spark-free tools.

Specifically, steel offers many advantages over other potential building materials in the construction field. It is.

◭ Durable

◭ Strong

◭ Easy to recycle

◭ Predictable and high quality when forged and finished in the proper manner

With many functional and aesthetic applications, steel is reliable and versatile. Plain steel can be further improved in a variety of processes, including the two detailed below.

What is the main difference between galvanized and stainless steel?

Galvanized Steel

"The defining attribute of galvanized steel is its zinc coating layer."

The defining property of galvanized steel is its zinc coating layer, which forms a protective layer against the combination of moisture and oxygen that would otherwise cause the metal beneath to rust. Rusting slowly but surely erodes steel, reducing its integrity and ultimately creating safety issues, whether the steel is used for purely functional applications or as part of an impressive custom facade or other design element.

Galvanizing uses plain steel or other metals, such as iron, with a zinc coating. This process can be accomplished in several different ways, helping to add versatility and allowing for easy galvanizing of many different types of steel and iron. The hot dip galvanizing process uses molten zinc to provide a strong, relatively thick coating on large pieces of steel. Meanwhile, hot-diffusion galvanizing is common for smaller metal parts, especially those with more complex designs. Both hot-dip galvanizing and hot-diffusion galvanizing have strong applications.

In general, galvanized steel is cheaper than stainless steel. It is also easier to work with while still retaining a great deal of strength, but not as strong as stainless steel.

One of the most visually memorable elements of galvanized steel is its versatile appearance. Depending on the specifics of the process, galvanized steel can have a consistent finish or a shiny finish, creating a unique look.

While the galvanizing process helps prevent rusting and provides corrosion resistance, it is important to note that it will eventually wear off, especially when exposed to high acidity or salt water. This is especially important near oceans and other bodies of seawater and in areas exposed to high levels of acid rain exposure.

Stainless Steel

"Stainless steel has built-in protection against rust and corrosion."

Stainless steel is an alloy made of iron, carbon and chromium, and sometimes other elements, such as molybdenum, which provide significant corrosion resistance. Rather than being immersed or coated in a protective layer like galvanized steel, stainless steel has this defense against built-in damage.

There are many different types of stainless steel available, each with a different composition and resistance to various forms of corrosion and damage. This is useful for design work where stainless steel components may be frequently exposed to corrosive chemicals or high temperatures in industrial applications and where alloys may be continuously exposed to salt water or acidic environments.

The manufacturing process makes stainless steel a more expensive option than galvanized steel. However, stainless steel is typically stronger than its galvanized counterpart.

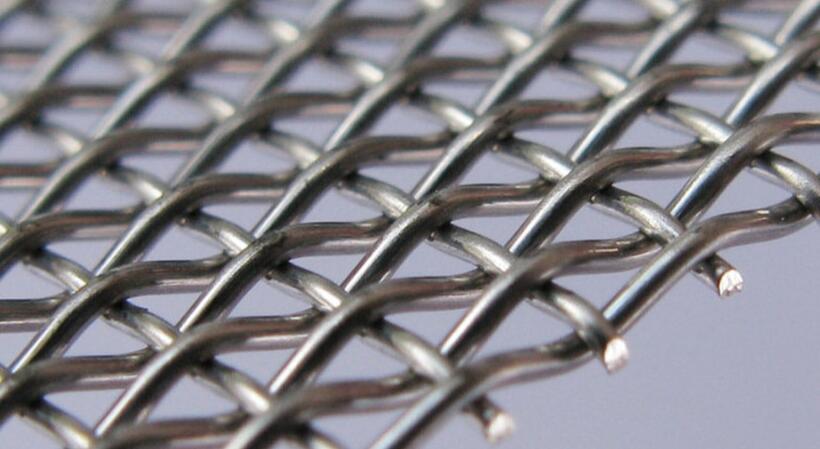

Stainless steel can also be finished in many different ways, providing a high degree of customizability in terms of final appearance. This aesthetic flexibility is particularly important for elevations and similar design elements that are highly valued for standing out from the crowd by providing memorable or unique visual hooks.

Is stainless steel compatible with galvanized steel?

In a sense, both types of steel can be assumed to be used in a single structural component, yes. Stainless steel has some form of compatibility with galvanized steel. However, direct contact between these metals can lead to severe corrosion if the correct conditions are met (e.g. high salt and moisture). In these cases, non-metallic materials should be used to avoid contact between the two types of steelmaking.

Which steel should you choose for your project?

There is no single, universally applicable rule to determine which steel is best for your particular project. Understanding the difference between galvanized and stainless steel can greatly assist you in making this important decision.

Galvanized steel offers a unique luster in the finishing process and can be used for decades in many environments before rust or wear becomes evident. However, stainless steel does not face the same specific weaknesses caused by salt water and acidic environments, and some varieties of this alloy can be designed in ways that address these issues. Combined with the many ways that stainless steel can be accomplished, this alloy solves many aesthetic and practical problems.

To learn more about the many ways stainless steel can be deployed in your next project, contact the experts at YKM today.