How to Judge the Quality of Epoxy Coated Wire Mesh

Mar. 28, 2022

How to choose a good quality epoxy coated wire mesh

Our customers are often cheated about the wire mesh coating by other manufacturers. So how to choose a good quality epoxy coated wire mesh, I will give advice from different perspectives:

1. longitude and latitude wire spread out evenly.

2. High quality epoxy coated wire mesh smooth touch, this aspect needs to be tested in person.

3. pull wire mesh face, can feel the structure is very solid.

4. The important is the quality of the epoxy coating .it have a great impact on the life of the product, if use the low quality epoxy coating, it will fall off soon, then the wire will rust.

Cartridge manufacturers know that epoxy coated wire mesh is an important part of the cartridge, the details determine success or failure, high quality support mesh can also improve the overall quality of the product. For more details about epoxy coated wire mesh, please check our website.

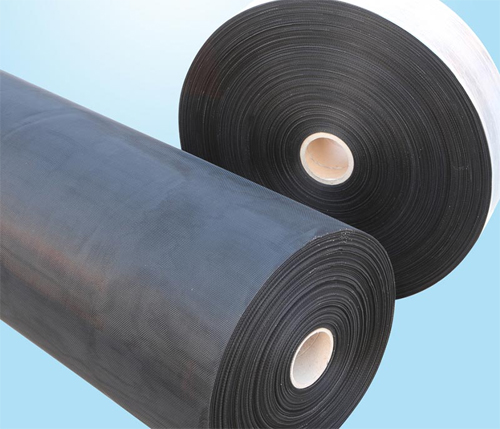

Product Description.

The manufacturing process of epoxy coated wire mesh is to use the principle of electrostatic spraying to adsorb the environmental protection epoxy resin powder on the surface of the wire mesh woven by different metal wires. After a certain time of high temperature curing, the epoxy resin powder melts and covers the substrate. A dense protective layer is formed on the surface of the mesh.

Epoxy powder is divided into indoor type and outdoor type, and special powder can be custom developed according to customer requirements.

Substrate mesh usually includes common steel mesh, aluminum alloy mesh and stainless steel mesh.

Epoxy mesh manufacturing standard: GB/T 17492-2019

Weave pattern: plain wave rough edge/wrapped edge

Features of epoxy coated wire mesh.

After epoxy coating the metal mesh has fixed interweaving points, vertical warp and weft, uniform mesh holes, not easy to loosen and deform, filter paper support reinforced, soft mesh surface, easy to fold and shape; uniform coating thickness, uniform and consistent color.

Applications and categories of epoxy coated wire mesh.

According to different applications, epoxy wire mesh can be divided into industrial epoxy wire mesh and civil epoxy wire mesh.

Industrial epoxy wire mesh mainly refers to aluminum alloy epoxy wire mesh and plain steel epoxy wire mesh, which are mainly used as filter element support mesh, such as hydraulic filter, air filters, and crude oil filter, etc.

Civil epoxy wire mesh mainly refers to stainless steel epoxy wire mesh, which is mainly used as security window screens in high-grade residential and commercial buildings.

Advantages of YKM epoxy coated wire mesh.

The mesh is square after coating, no deformation, smooth surface, maximum undulation height of platform ≤10mm. powder coating volume is controlled at 20-35g/㎡, with moderate interlacing points. The width of finished product can reach 1600mm.

The surface treatment powder adopts low temperature fast curing oil resistant matting resin paint (160℃/90s) and low temperature curing weather resistant matting polyester paint (160℃/90s). The powder is RoHS and REACH certified.

It is resistant to oil immersion and corrosion. It can pass the test of various brands of hydraulic oil media in the world at different temperatures and different times. There is no change in the surface of the coating. It is suitable for high temperature and high pressure special hydraulic filtration products.

Weather corrosion resistance, according to ASTM B117-09 salt spray test standard, the surface of the coating remains unchanged for 96H continuous test, suitable for harsh environment air filters and outdoor environment.

High adhesion strength, can pass H grade pencil test, 1kg/50cm impact test, scratch test, fatigue resistance test.

High bending strength, can be folded by a steel rod with 1mm radius of curvature, no cracks on the surface

Industrial selection of high quality steel and drawing and annealing process, combined with new weaving process, the mesh surface is soft and low elastic modulus.

After coating, it is easy to fold and shape. The warp and weft threads are firmly combined after product processing and are not easy to fall off. The edges will not fall off after longitudinal cutting.

The adhesion of coated interweaving point can reach 0.7kg.