What is the Difference Between Stainless Steel Screen and General Mesh Products?

May. 28, 2021

As a Stainless Steel Wire Mesh Supplier, share it with you.

Stainless steel screens are different from general mesh products. Instead, there are strict series of mesh sizes. And there are mesh products that are recognized by industries, institutions, and standards that can classify and screen object particles. Screen does not talk about "mesh", "mesh" is just a habit of people to describe the screen, it is difficult to overcome for a while. The screen is different from the general mesh products in that it has a strict mesh size instead of using "mesh" to express. The size of the screen is not isolated, it has a series of mesh sizes, and the purpose is to screen by classification. Only such a mesh product can be called a screen.

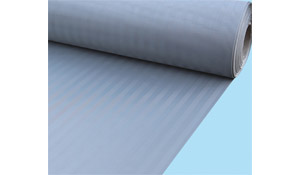

Fine Stainless Steel Wire Mesh

304 steel is resistant to corrosion by sulfuric acid, phosphoric acid, formic acid, urea, etc., suitable for general water, control gas, wine, milk, CIP cleaning fluid and other occasions with little corrosiveness or no contact with materials. 316L steel grade has added molybdenum element on the basis of 304, which can significantly improve its resistance to intergranular corrosion and oxide stress corrosion and reduce the tendency of hot cracking during welding. It also has good resistance to chloride corrosion. It is often used in pure water, distilled water, medicine, sauce, vinegar and other occasions with high hygiene requirements and strong medium corrosion performance. The price of 316L is almost twice that of 304. The mechanical properties of 304 are better than 316L. Because of the corrosion resistance and heat resistance of 304 and 316, they are used as stainless heat-resistant steel. The strength and hardness of 304 and 316 are similar. The difference between the two is that the performance of 316 is much better than that of 304. The more important point is that molybdenum metal is added to 316, which improves the heat resistance.

We can use paint or oxidation-resistant metal to electroplate the surface of carbon steel, but this kind of protection is only a thin film. If the protective layer is damaged, the steel underneath will begin to rust. The properties of stainless steel depend on the chromium element. When chromium is added at 10.5%, the corrosion resistance of stainless steel will increase significantly, but if the chromium content is higher, although certain performance can be improved, it is not obvious. The reason is that this treatment method changes the type of surface oxide to a surface oxide similar to that formed on pure chromium metal, but this oxide layer is thin, and the natural luster of the steel surface can be directly seen through it. Make stainless steel have a unique surface. Moreover, if the surface layer is destroyed, the exposed steel surface will react with the atmosphere. This process is actually a self-repairing process, so that the passivation film is re-formed, which can continue to play a protective role. ``Therefore, all stainless steels have a common feature, that is, the chromium content is above 10.5%, and the better steel grades also contain nickel, such as 304. The addition of molybdenum can further improve the atmospheric corrosion, especially the corrosion resistance of the chloride-containing atmosphere, and 316 belongs to this kind.

Our company also has Fine Stainless Steel Wire Mesh on sale, welcome to contact us.